Tel: +86-19906868508

E-mail: info@sihanmed.com

Tel: +86-19906868508

E-mail: info@sihanmed.com

The high-frequency electrosurgical knife consists of a host and accessories such as the negative plate. It has functions such as monopolar electrocutting. Low-frequency current can produce obvious electric shock effects. The selected frequency is required not to cause electric shock. Usually, the frequency should be higher than 300kHz. When the AC frequency is 500kHz, the current has less electrical stimulation to the human body. Due to problems such as high-frequency radiation, the working frequency of the high-frequency electrosurgical knife is 0.4-3MHz. During monopolar electrocutting, the output end of the high-frequency electrosurgical knife is connected to the electrosurgical knife head. During monopolar electrocutting, the contact area between the blade head and the body tissue is small, and high heat is generated to vaporize the body tissue instantly. Monopolar electrocutting is divided into pure mixed cutting, which closes the capillaries at the same time and is the most commonly used working method during surgery.

Common faults of high-frequency electrosurgical knife include sudden alarm of the negative plate when it is turned on, usually due to damage to the knife handle switch, damage to the electrode wire, etc.; the instrument cannot self-check mainly due to problems with the AC voltage power supply, and the power of electrocoagulation and electrocuting cannot be adjusted during application, mainly due to the panel connection cable falling off, etc.; the panel buttons fail during use, usually due to the circuit fuse being blown, etc. When the DD-2 high-frequency electric knife was started, it was found that there was no indication on the panel after it was turned on. Analysis showed that there was no 220V power supply voltage in the AC power supply, and the output voltage Vcc of the voltage regulator had no 5V voltage. Troubleshooting: Using a multimeter to test the AC power supply voltage was 220V. The multimeter test showed that the fuse was blown. After replacing it, the machine was turned on for heat dissipation. There was no indication on the panel. The instrument housing was removed to test the relay, which was normal. The test showed that V1 was broken and the fault was eliminated after replacement. The negative plate alarm sounded when the Taiwan Yuesheng 300 high-frequency electric knife was turned on. Analysis showed that the electrode wire was broken. Troubleshooting: Check that the electrode wire was normal. Remove the high-frequency electric knife housing and observe the metal head in the jack and take it out. After turning it on, there was no output from the knife handle. The self-priming of the relay was observed to be normal. Use a multimeter to test the power tube and find that it was damaged. Replace it and the fault is eliminated.

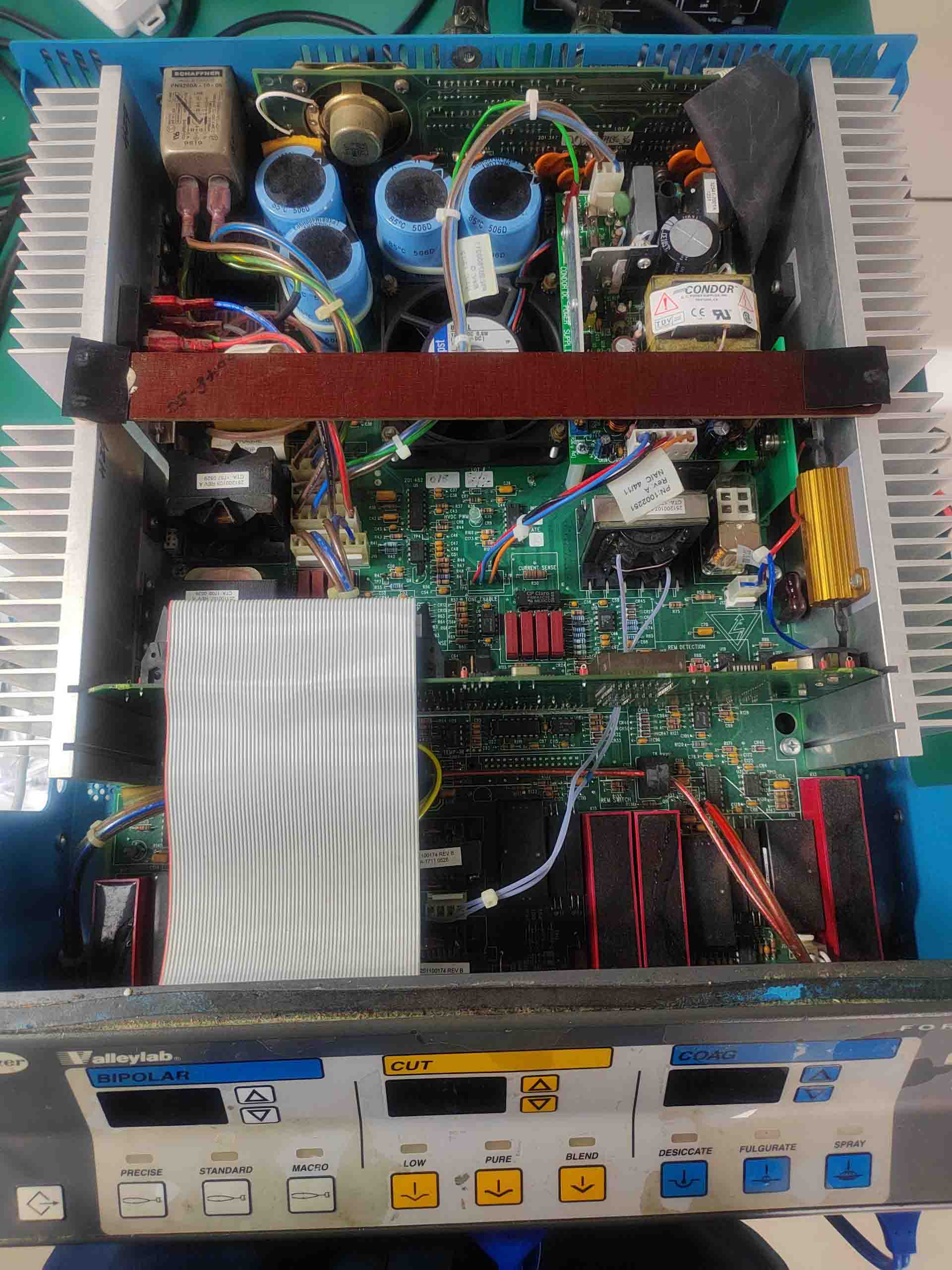

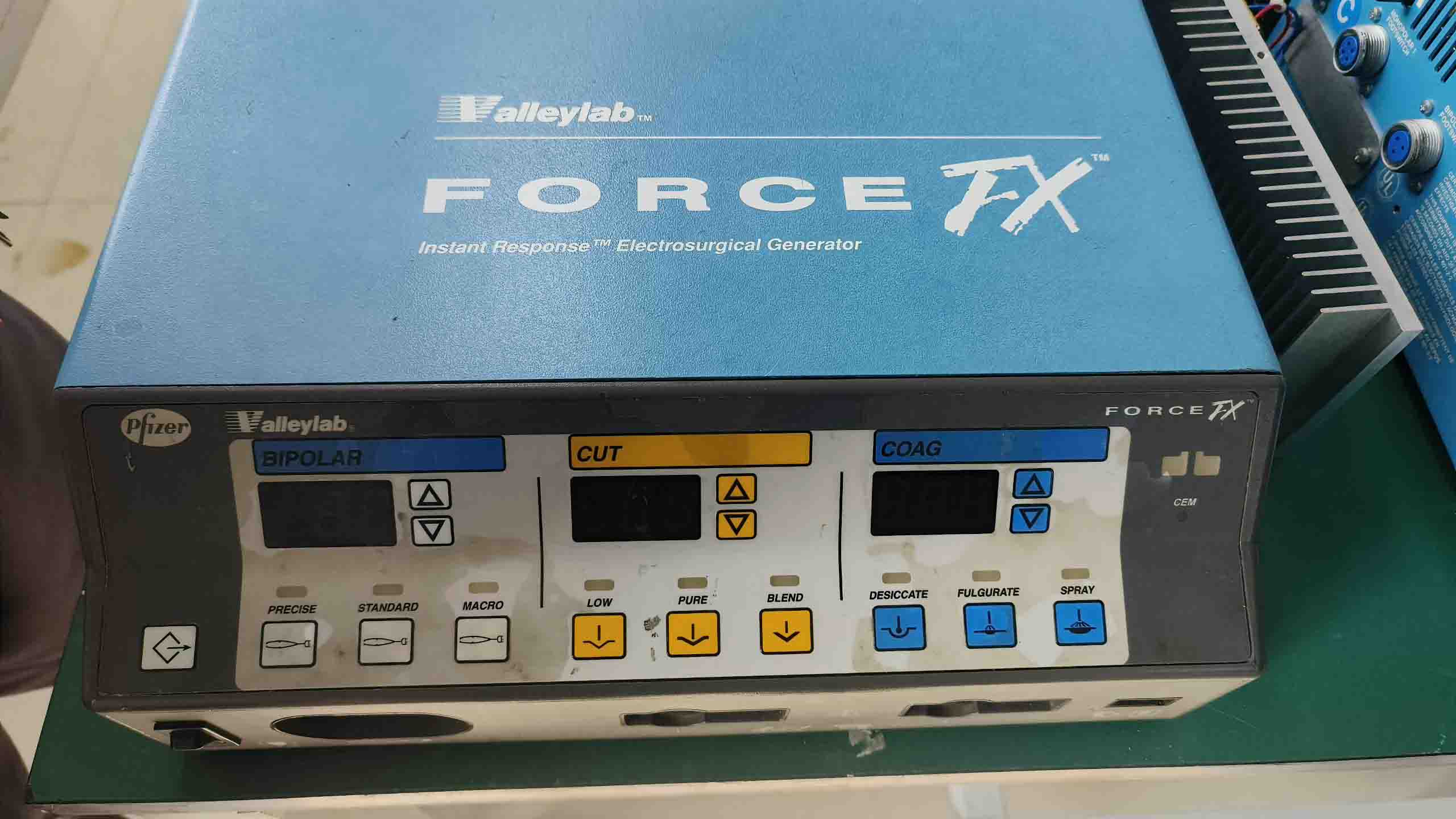

Equipment model: FORCE FX-8

1. Appearance inspection: Check the appearance of the main unit to see if it is intact and there is no obvious sign of external damage.

2. Power-on test: Error 212 is reported when the machine is turned on.

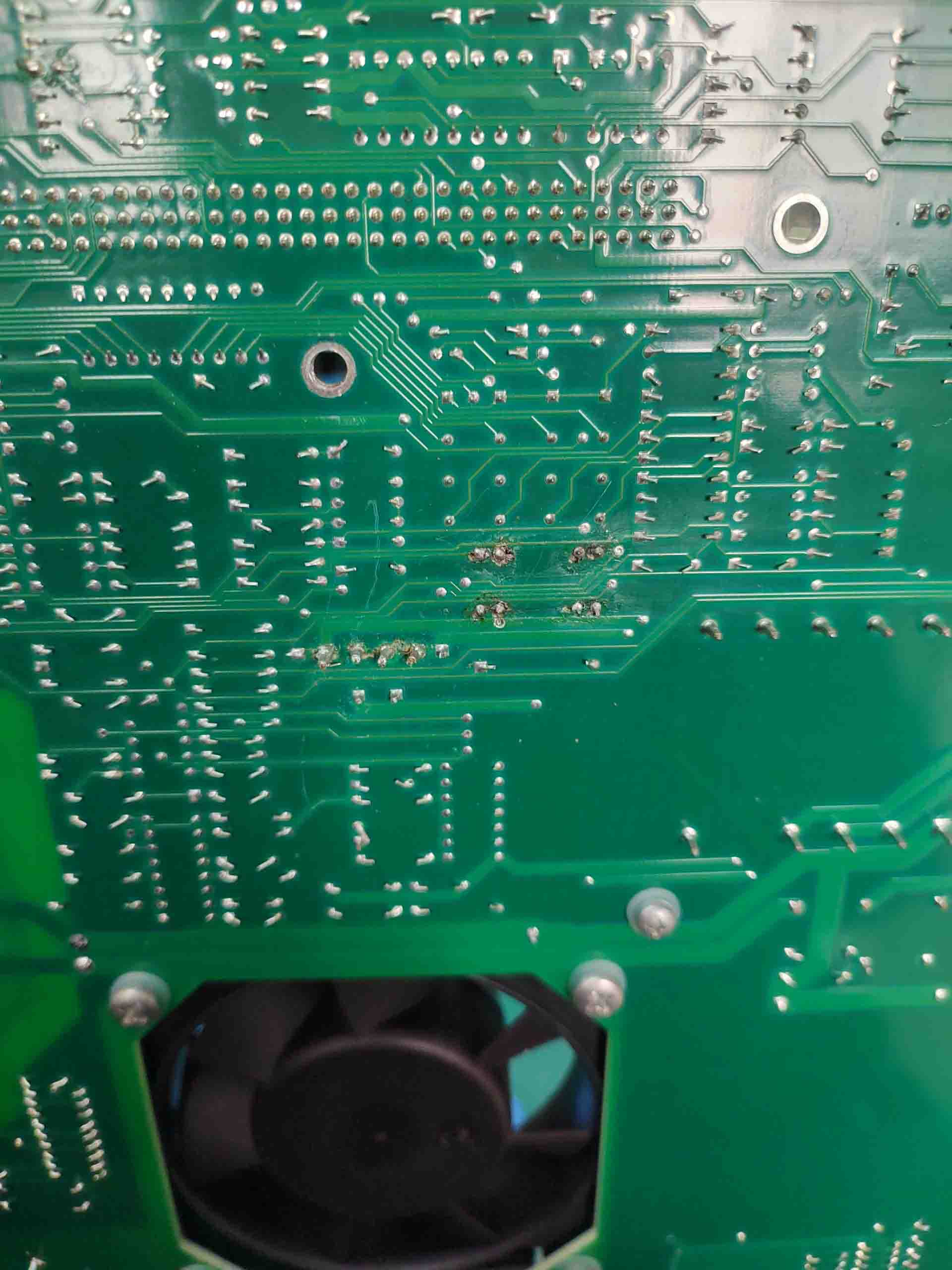

3. Disassembly test: Error 212 is a motherboard failure. The detection chip output is abnormal and the numerical deviation of several signal points is too large. The chip needs to be replaced to calibrate the relevant parameters. After 212 is resolved, the detection found that the electric coagulation is low. The cause of the failure is analyzed as serious aging of the bottom board components, carbonization of the relay, and unstable chip operation.

4. Repair plan: ① Replace the bottom board ② Replace the relay ③ Repair the main board ④ Calibrate the output voltage and strengthen the internal firmware.

Repair cycle: 4 working days