Tel: 4008-266-720

E-mail: info@sihanmed.com

Tel: 4008-266-720

E-mail: info@sihanmed.com

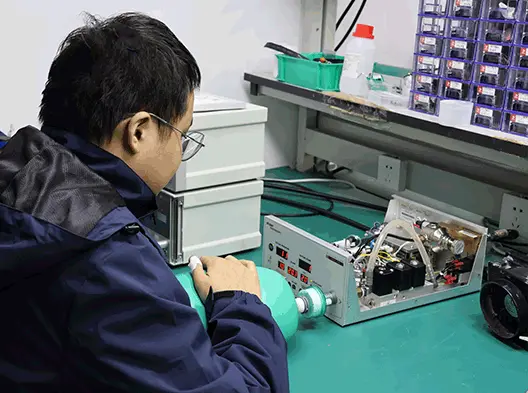

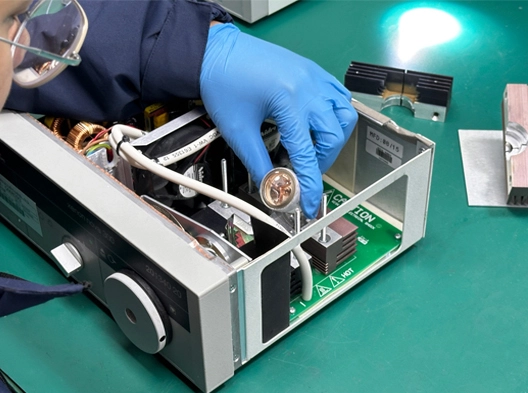

Our endoscope equipment repair service is professional and reliable, and the repair team is composed of experienced experts. We specialize in insufflator repair, medical monitor repair, Xenon light source repair, electrosurgical generator repair, camera console repair and other repair projects to ensure that your equipment operates at optimal performance. Excellent service quality and fast repair time allow every customer's medical practice to run smoothly.

SIHANMED is ready to offer you services of medical monitor repair, bronchoscopes, cystoscopes, and electrosurgical generator repair, etc to solve common endoscope equipment problems.

Electrosurgical Generator Common Problems:

Error code

No output

Low/High output power

For all these issues, electrosurgical generator repair services offer specialized solutions. As one of the leading endoscope repair companies, our technicians can diagnose error codes, restore output functionality, and recalibrate your equipment to ensure optimal performance. By addressing these common problems through professional repair services, you can maintain the reliability and efficiency of your surgical equipments, ensuring the highest standards of patient care.

Insufflator Common Problems:

Error code

Sensor broken

Unstable pressure

No output flow

For instance, the Olympus UHI-4 insufflator is known for its reliability, yet it can still face these common problems. When such issues arise, Olympus UHI-4 insufflator repair services become crucial. Our expert technicians can diagnose and fix these problems, ensuring that the insufflator delivers consistent gas flow and accurate pressure regulation.

Light Source Common Problems:

Power board broken

Lamp life expired

Dark light

As a professional endoscopy repair service provider, we can provide comprehensive diagnostic and repair services, including light source troubleshooting, lamp replacement, fiber repair, cooling system maintenance, and power module inspection and repair, ensuring that your device is always in the best working condition.

Camera Processor Common Problems:

No output image

Can't recognize the camera

Socket broken

Overheat

The endoscopy processor overheating may cause the device to automatically shut down or endoscope instruments performance to deteriorate.

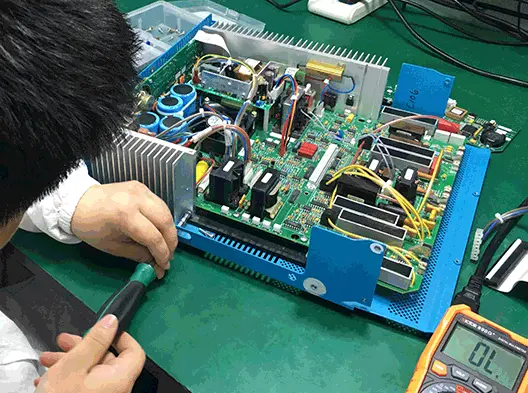

1. Complexity of fault diagnosis

As a complex medical device that integrates power module, control module, gas pipeline and various functional valves (including pressure reducing valve, flow control valve, safety valve, etc.), the failure of insufflator may come from many aspects. Insufflator repair personnel need to have rich professional knowledge and practical experience to accurately determine the fault.

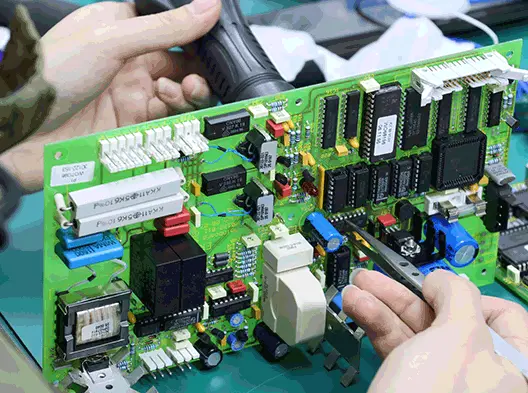

2. Repair of high-precision components

The medical insufflator contains many high-precision components, such as pressure sensor, flow sensor, temperature sensor, etc. The repair of these components requires professional tools and techniques to ensure that their accuracy and performance are not affected.

3. Sealing maintenance of gas system

The gas system of the insufflator needs to maintain a high degree of sealing to ensure the stable transmission of CO2 gas. However, in actual use, due to various reasons (such as aging of pipelines, loose connections, etc.), the gas system may leak. When repairing the insufflator, it is necessary to carefully check and replace aging or damaged pipelines and seals, and also to perform air tightness tests to ensure that the gas system of the insufflator is well sealed.

4. Guarantee of safety performance

As a medical device, the safety performance of the insufflator is of vital importance. During the insufflator repair process, maintenance personnel need to strictly abide by relevant safety regulations and operating procedures to ensure that the repair process will not cause safety hazards to the equipment or patients.

1. Complexity of fault diagnosis

As a complex medical device that integrates power module, control module, gas pipeline and various functional valves (including pressure reducing valve, flow control valve, safety valve, etc.), the failure of insufflator may come from many aspects. Insufflator repair personnel need to have rich professional knowledge and practical experience to accurately determine the fault.

2. Repair of high-precision components

The medical insufflator contains many high-precision components, such as pressure sensor, flow sensor, temperature sensor, etc. The repair of these components requires professional tools and techniques to ensure that their accuracy and performance are not affected.

3. Sealing maintenance of gas system

The gas system of the insufflator needs to maintain a high degree of sealing to ensure the stable transmission of CO2 gas. However, in actual use, due to various reasons (such as aging of pipelines, loose connections, etc.), the gas system may leak. When repairing the insufflator, it is necessary to carefully check and replace aging or damaged pipelines and seals, and also to perform air tightness tests to ensure that the gas system of the insufflator is well sealed.

4. Guarantee of safety performance

As a medical device, the safety performance of the insufflator is of vital importance. During the insufflator repair process, maintenance personnel need to strictly abide by relevant safety regulations and operating procedures to ensure that the repair process will not cause safety hazards to the equipment or patients.

Properly manage the endoscope equipment by wearing gloves and gripping the external section of the eyepiece.

Refrain from touching the eyepiece lens or the objective lens to prevent contamination. Even the slightest presence of dust, dirt, or fingerprints can lead to undesirable image quality.

Keep track of the Light Source's operational hours, and replace the bulb if it has been in use for over 500 hours.

Utilize Chempad Alcohol wipes to thoroughly clean the external surface of the machine, eliminating dirt and dust.

Enhance image and video display quality by applying Screen Prep to clean the monitor and reduce dirt attraction.

Test the Light Source by powering it on, ensuring that the emitted light's intensity changes appropriately when adjusting the brightness knob.

Clean the Light Source by removing dirt and dust with chamois tip swabs.

Connect the endoscope to the Light Source and power on the machine. Confirm the seamless connection and check for a visible display on the monitor, ensuring that your system is ready for operation.

Gently detach the Light Source and embark on a thorough cleaning process for the camera lens. Employ the precision of Optic Preps and Chemswab alcohol swabs to meticulously eliminate even the minutest dust particles, preserving the clarity and precision of your imaging.

Bestow upon the endoscope's body the grace of Chempad alcohol wipes. This meticulous cleansing ritual ensures the overall cleanliness of the endoscope, serving as both a preparatory step before sterilization and a daily operational guardian against contaminants.

With a discerning eye, inspect the image quality on the display. Confirm that the camera remains 100% free from dust or dirt, presenting a clear image without any hint of blurring, distortion, or discoloration. This step guarantees that your imaging is consistently of the highest standard.

Conclude the maintenance routine with a white balance test, orchestrating the colors on the display to perfection. This ensures the clearest display, enhancing the visual experience and maintaining the integrity of your imaging system.

When you encounter a professional problem that cannot be solved by yourself, consult the medical monitor repair team in time to assist you to prevent the error from worsening.

Begin the maintenance ritual by delicately wiping the entire surface of the insufflator machine with Chempad Alcohol wipes.

Turn your attention to the intricate network of cables and tubing. Thoroughly inspect them for any signs of leaks or damaged wires.

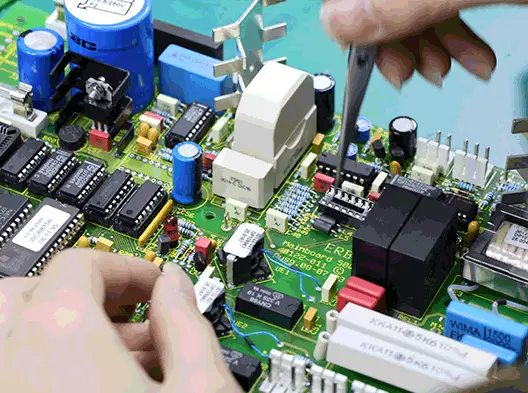

Delve into the heart of the insufflator and focus on its circuit boards. Employ the precision of Chemtronics Duster to gently sweep away any accumulated dust, unveiling the brilliance of the circuitry.

Conclude the maintenance routine by conducting a comprehensive test on the insufflator.

Quick response and diagnosis: Upon receiving a repair request, we will immediately arrange for professional technicians to conduct a preliminary diagnosis. Our medical monitor repair covers: Monitor screen failure, power problems, signal loss, touch screen problems, audio function failures, overheating problems, software problems, etc.

Professional technology and equipment: Our medical monitor repair team consists of experienced engineers with deep professional knowledge and rich repair experience. We conduct regular training to ensure that technicians have the latest knowledge of medical monitor repair technology and equipment. Our professional technology and equipment ensure the quality and efficiency of repairs.

Comprehensive after-sales service and support: We not only provide medical monitor repair services, but also focus on after-sales support and customer satisfaction. After the repair is completed, we will explain the cause of the failure and the repair process to the customer in detail, and provide maintenance suggestions.